Deep Sea Sampling research project

The global demand for rare earths, copper and cobalt is already huge and will continue to rise in the coming years. Electrification and the energy transition are significantly accelerating this development. New deposits must be developed to meet the long-term demand for raw materials.

There is great potential in as yet unexplored deposits in the deep sea, which can be found from a depth of 2,000 metres below sea level. Under these adverse conditions, new machines and technologies are required for exploration and extraction - and this is precisely what the joint project Deep Sea Sampling, funded by the Federal Ministry of Economics and Climate Protection (BMWK) and now honoured with the Bauma Innovation Award, is working on.

The project partners are TU Bergakademie Freiberg with its Institute for Processing Machines and Recycling Systems Technology and the Institute of Mechanical Engineering, the University of Rostock, FAU Erlangen-Nuremberg, Krebs & Aulich GmbH and BAUER Maschinen GmbH. The Federal Institute for Geosciences and Natural Resources (BGR) and the Deep Sea Mining Alliance (DSMA) are also represented on the project committee.

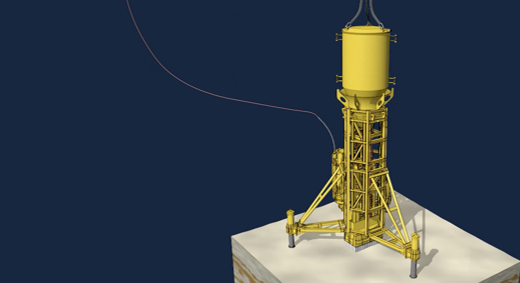

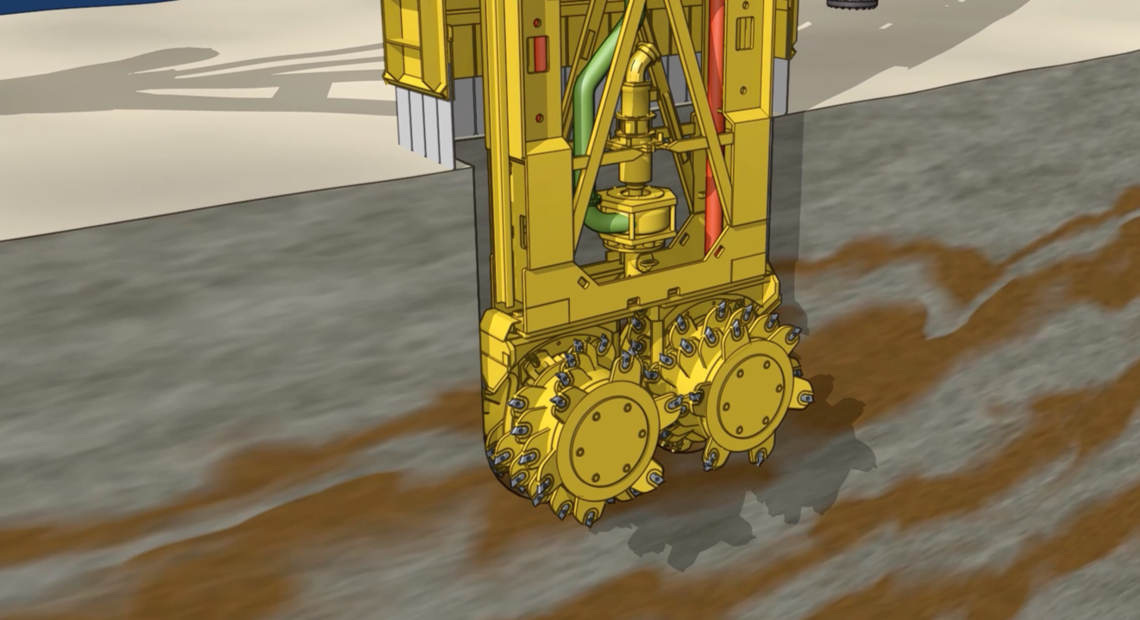

The three-year research project will start in 2021. The aim is to electrify a compact diaphragm wall cutter and transform it into a smart, semi-autonomous vertical mining unit instead of a planar approach to extracting the raw materials. The aim is not only to ensure minimally invasive, efficient resource extraction, but also to capture any resulting clouds of debris by working in a closed, shielded process.

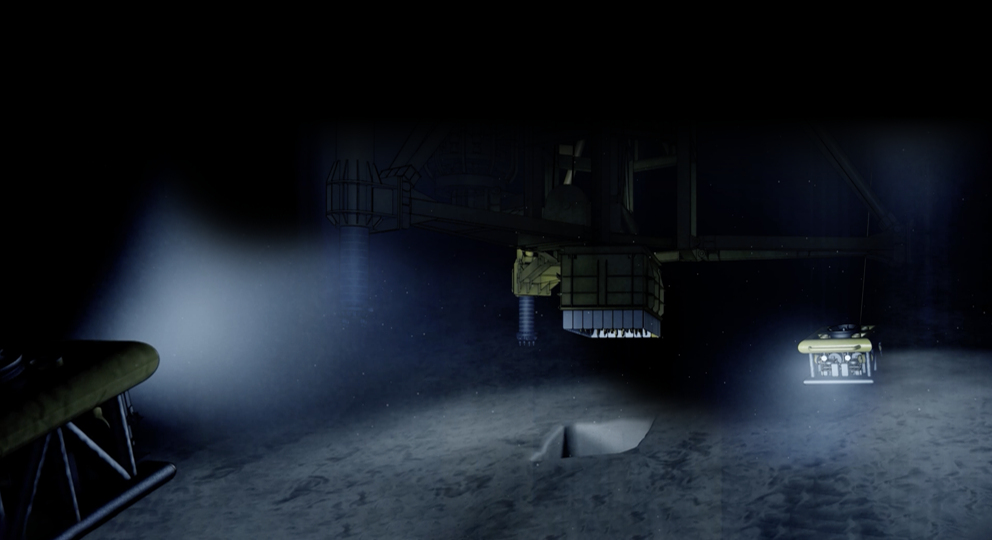

However, numerous factors must be taken into account when developing such an innovative technology: For example, water pressures of up to 400 bar, complete darkness and temperatures of around 1°C prevail on the seabed - enormous challenges for the machine technology. Added to this are the nature of the massive sulphide deposits with their fissured surfaces and extreme slopes.

Krebs & Aulich is responsible for developing the electric drive for the diaphragm wall cutter as part of the project.